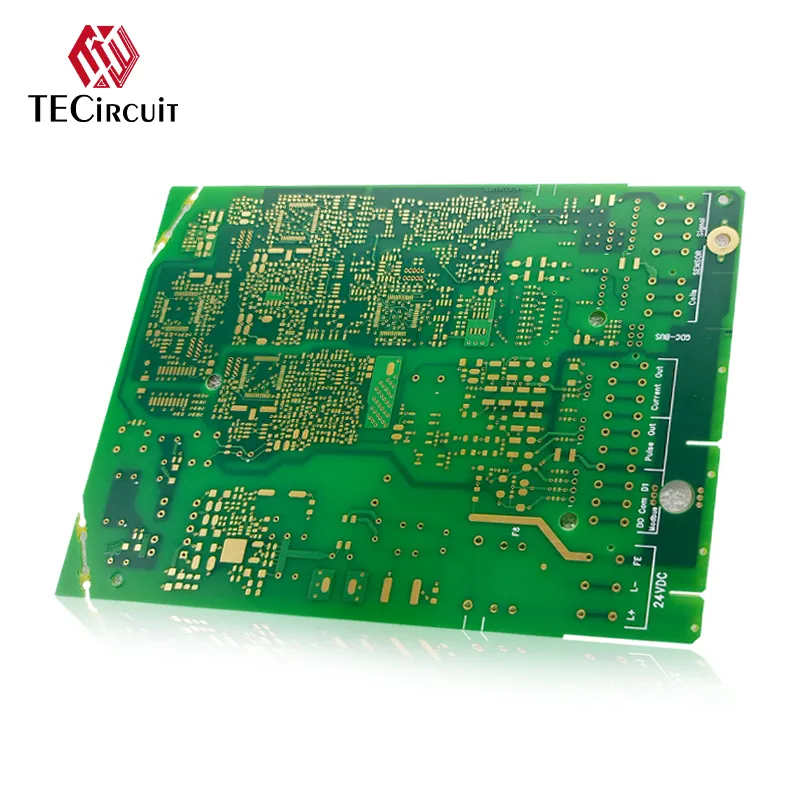

Arising Applications of RIGID PCBs in IoT and Wearable Devices

In the existing technology landscape, the demand for compact yet trustworthy circuitry services goes to an all-time high. This is especially evident in the Net of Points (IoT) and wearable gadget industries, where technology drives the marketplace. One simple hero of this technological change is the RIGID Printed Circuit Board (PCB). Inflexible PCBs are at the leading edge of IoT and wearable device growths, supplying robust systems for advanced electronic devices. This blog site article discovers how inflexible PCBs are progressively forming the future of devices that are pushing the boundaries of connection, ease, and design.

Integrating RIGID PCBs in Next-Generation IoT Gadgets

The heart of any electronic tool is the PCB, and the function of RIGID PCBs in IoT can not be overstated. RIGID PCBs supply stability and toughness that are critical in housing elements for different IoT applications. As IoT gadgets advancement in complexity and diminish in size, stiff PCBs continue to be the best remedy for making sure the stability of device structure while likewise making it possible for the assimilation of sophisticated sensing units and processors.

Among the essential obstacles in IoT layout is suiting sensing unit varieties, microcontrollers, and extra electronic devices without endangering the device's durability or form variable. Inflexible PCBs master offering the skeletal structure required to sustain these digital components. Their flat and stiff nature is flawlessly suited to the demands of sensing unit integration and space optimization, which are important in IoT applications.

Durability, Thickness, and Efficiency

Stiff PCBs are favored for their robustness, and when made use of with IoT gadgets in industrial or severe environmental settings, they provide an unequaled degree of protection against mechanical tension and thermal pressure. The enhancing miniaturization of parts is enabled by the high thickness electrical wiring capabilities of inflexible PCBs, enabling complex wiring in a limited room without compromising dependability or efficiency.

The Evolution of Wearables: How RIGID PCBs Are Forming the Market

In the world of wearables, we are witnessing a change from the clunky models of the past to sleek, functional tools that incorporate seamlessly right into our everyday lives. This transformation is mostly driven by the adaptability of stiff PCBs. Wearables require special layouts that can flex without breaking, and here, RIGID-FLEX PCBs stick out.

Adaptability Without Compromise

RIGID-FLEX PCBs combine the advantages of inflexible and adaptable circuits, permitting 3D shapes and flexes within a device. This evolutionary step has actually allowed the advancement of wearables that satisfy the shapes of the human body without endangering on the required connection honesty. These advancements have actually led to the production of smartwatches, fitness trackers, and health displays that are comfy to put on and reliable in operation.

Power Administration Solutions for IoT Tools Using RIGID PCBs

Power effectiveness and power management are vital in the globe of IoT. flex pcb , specifically those operating in remote or unattainable locations, depend on effective use energy to preserve durability and reduce maintenance requirements. RIGID PCBs play a pivotal duty in enhancing power management remedies, using a platform for carrying out innovative power-saving innovations such as power gating, rest settings, and even energy harvesting.

trulieve pcb and the Function of RIGID PCBs

Energy harvesting is a game-changer in IoT, as it gives a method to power tools with the collection of ambient energy sources like light, warmth, and motion. RIGID PCBs with incorporated power gathering modules convert these gathered powers into a stable power supply, expanding the operational life of IoT tools without the demand for normal battery replacements or recharging.

Enhancing Connection Includes with Advanced RIGID PCB Designs

Smooth connectivity is a defining attribute of IoT gadgets. Inflexible PCBs support a host of connectivity functions, including sophisticated antennas, NFC components, and Bluetooth modern technologies, to make sure remarkable communication in between devices and networks. The application of these technologies varies from wise home automation to commercial sensor networks, underscoring the flexibility of stiff PCBs in contemporary electronic devices.

Advanced Antennas and Signal Integrity

For IoT gadgets to operate ideally, their antennas need to be developed for the specific frequencies and interaction criteria they will make use of. RIGID PCBs provide a stable, interference-resistant system for these tailored antennas, ensuring that signal stability is maintained in a variety of use circumstances. The integration of advanced antennas in RIGID PCB styles helps with long-range interaction and improves the total efficiency of IoT devices.

Security Considerations in IoT and Wearable Device PCBs

As the number of linked devices proceeds to expand, so does the concern for protection. RIGID PCBs, when made with high-security requirements in mind, provide a structure that can sustain safe elements such as TPMs and safe territories. Physical meddle resistance is an additional intrinsic advantage, as inflexible PCBs are extra difficult to control than their versatile equivalents.

Creating for Security

Including security features right into the PCB design first is important. Inflexible PCBs, with their layer stack-up styles and controlled resistance directing, can function as an obstacle against breach attempts. When integrated with security and robust verification methods, RIGD PCBs are integral in ensuring that IoT and wearable gadgets are protected against unauthorized access and data violations.

Finally, inflexible PCBs are driving innovation in IoT and wearables by giving a steady and dependable foundation for sophisticated electronic devices. Their stamina, adaptability, and high-performance characteristics make them an excellent choice for tools that require to operate in a large range of problems. As the IoT and wearable sector remain to evolve, RIGID PCBs will most certainly remain an essential enabler of the future generation of clever, connected devices.