Enhancing Accuracy: The Power of Silicone Rubber Tubes in High-Efficiency Applications

The contemporary industrial landscape is an intricate tapestry of precision, efficiency, and development. As technology breakthroughs, the need for materials that can endure severe problems, all the while preserving their functional stability, has never ever been greater. For engineers and makers taken part in high-efficiency applications, silicone rubber tubes have actually risen to importance as a keystone of item design and development, offering a versatile option to an array of challenges.

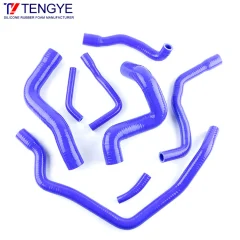

From microwave healing to pipes design, silicone rubber tubes supply an excellent equilibrium of strength and adaptability, important for applications in aerospace, health care, and the automobile sectors, to name a few. This blog site message dives deep into the textile of silicone rubber tubes, uncovering how variants in material and manufacturing can provide to one of the most complex demands of modern-day market.

Navigating the World of Microwave Treating Silicone Rubbers

In the world of fast curing procedures, microwave modern technology has emerged as a game-changer, and silicone rubber plays a crucial role. Microwave healing silicone rubber tubes use unparalleled speed and efficiency, considerably reducing production times compared to traditional techniques. Microwave energy flusters the molecular structure of the silicone, accelerating the cross-linking process and causing an exceptional, heat-resistant item.

For markets concentrated on high-volume output, such as electronics and telecommunications, microwave curing silicone rubber tubes supply an essential advantage. The high dielectric stamina and thermal stability of these tubes ensure longevity popular electric applications. With minimized energy consumption and cycle times, makers can optimize their assembly line for peak efficiency without compromising on high quality.

The Benefits of Fluorosilicone Rubber for Flexible Tubes Solutions

Flexible tubing is a keystone of numerous detailed systems, specifically those that come into contact with extreme chemicals or extreme temperature levels. Fluorosilicone rubber attracts attention as a specialized product known for its exceptional resistance to fuels, oils, and solvents. This makes it an ideal prospect for applications such as fuel lines, hydraulic systems, and within the marine industry.

The flexibility of fluorosilicone rubber ensures that flexible tubing preserves its structural integrity over time, even when revealed to one of the most aggressive atmospheres. Its low compression collection residential or commercial properties and capacity to preserve flexibility across a wide temperature array make sure consistent performance, making it a dependable remedy for high-efficiency systems that can not manage downtime.

Tailoring Silicone Rubber Tubes for Non-Porous Applications

In sectors where contamination is not a choice, the non-porous nature of silicone rubber tubes is a vital feature. In healthcare, pharmaceuticals, and food processing, the highest possible degrees of health and product purity must be preserved. tube of silicone , as its safe, non-stick top qualities make it the material of option for non-porous tube options.

Accuracy extrusion methods make it possible for producers to generate silicone rubber tubes with smooth, glass-like surfaces that hinder the development of bacteria and prevent contamination. Whether facilitating the transfer of important fluids or playing a function in packaging, these tubes are an essential element for making sure top quality and safety in high-efficiency applications.

Leveraging Thermoplastic Resins for Boosted Tube Shrinking

Thermoplastic resins are a functional team of materials that, when combined with silicone rubber, can produce tubes with special buildings. One of one of the most compelling attributes is the capability to produce silicone rubber tubes with controlled shrinkage. This can be critical in applications where a safe, tight-sealing fit is important to avoid leakages or ensure insulation.

For instance, in the vehicle market, silicone rubber tubes with controlled shrinking are widely utilized for cable television and cable harnessing. By very carefully adjusting the extrusion procedure, producers can dictate the last diameter and wall density of the tubes, using tailored services for different parts and systems within cars.

Cutting-Edge Processes for Production Silicone Water Piping

Pipes are indispensable components throughout numerous fields, from domestic plumbing to industrial flow systems. silicone tube supply an engaging choice to typical materials like PVC or copper. Silicone's resistance to scaling and rust, incorporated with its pliability and convenience of setup, make it a robust and reliable solution for water management systems.

Advanced making procedures, such as 3D printing and precision molding, have actually pushed silicone pipes right into the future. These strategies permit the development of intricate shapes and styles that cater to certain flow demands, whether in a house tap or a huge industrial cooling system. With technologies in silicone formulations, water pipes currently can deliver not just water, but likewise enhanced longevity and durability.

The journey with the globe of silicone rubber tubes is one of resourcefulness and continuous development. From their duties in essential applications to pioneering manufacturing processes, the adaptability and resilience of silicone rubber tubes make them important in our mission for high-efficiency systems and solutions. As we create in advance, it's clear that silicone rubber modern technology will certainly continue to play a leading role fit the commercial landscape of tomorrow.