Enhancing Sheet Steel Fabrication for Sustainable Manufacturing

In the context of our evolving environmental awareness, lasting production has actually come to be greater than just an appealing phrase-- it's a responsibility that the market have to take on. One industry that's increasing to the challenge is sheet metal fabrication. This procedure, important to developing components for a range of products, can be optimized for sustainability in a myriad of methods. Below's a deep-dive right into just how the sheet metal manufacture sector is building in advance with environment-friendly methods without compromising on high quality.

Eco-Friendly Practices in Sheet Steel Manufacture

For sheet steel construction to be sustainable, the starting factor should be a conscious effort to reduce the environmental impact of the process. This consists of everything from devices and material choice to scrap mitigation and energy-efficient procedures.

The Role of Recycled Materials in Modern Steel Sheet Production

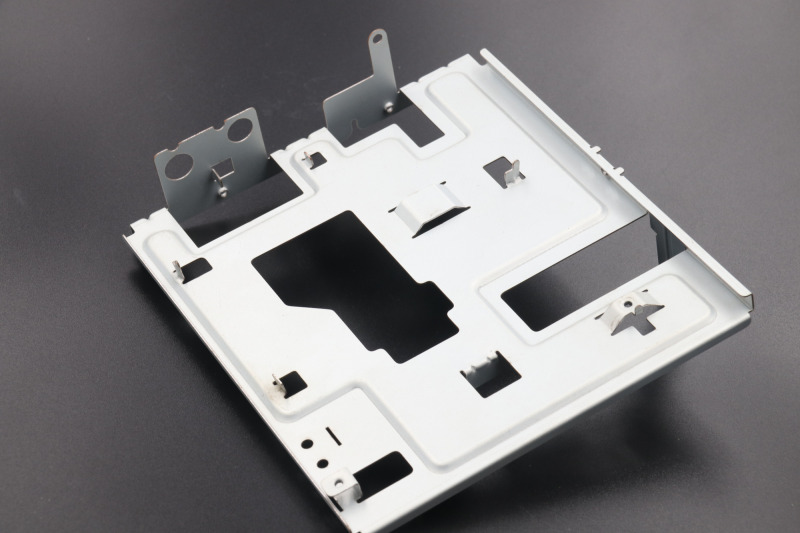

One of the most considerable changes towards sustainability has been the assimilation of recycled materials into the manufacturing of steel sheets. These materials, often scrap metal from previous production procedures, minimize the demand for brand-new ores, consequently conserving natural resources and energy. metal sheet fabrication is significantly purchasing devices that can take care of a greater percentage of recycled web content, guaranteeing that every sheet that's cut and bent is an action towards a greener future.

Minimizing Waste through Reliable Sheet Steel Layout and Nesting

Waste reduction begins with style. By utilizing lean principles and progressed computer modeling, fabricators can create effective component styles that minimize the quantity of unused material. Nesting software application better optimizes this process by arranging individual components in a manner that decreases scrap and increases the number of components that can be generated from a solitary sheet. These simple yet efficient techniques can bring about a considerable reduction in material waste.

Energy-Saving Technologies in the Sheet Metal Sector

The sheet steel market generally consumes a large amount of power as a result of the heats required for reducing, creating, and completing. Nonetheless, advances in technology deal options that significantly decrease energy intake without compromising efficiency.

The Adoption of Laser Cutting and High-Efficiency Presses

Laser reducing, with its precision and minimized material warping, is not just a game-changer in terms of quality yet likewise in energy performance. Compared to typical mechanical reducing techniques, lasers take in less power and generate much less product waste. Likewise, high-efficiency presses require much less power to form metal, and when combined with energy recovery systems, can cause significant cost savings.

Renewable Energy Assimilation

Numerous forward-thinking sheet metal manufacture centers are relocating in the direction of or have currently carried out renewable resource sources, such as solar panels and wind turbines, to power their operations. This not only reduces the greenhouse gas exhausts connected with typical power generation yet likewise guards producers from the volatility of fossil fuel rates. In addition, some are turning to green power tolls, which sustain the generation of eco-friendly electrical power.

Sustainability in Powder Coating Processes

Powder layer, the procedure of using a dry powdered paint to a steel component, is one more area where sustainability can be considerably boosted. Typical liquid paints often consist of high degrees of unstable organic compounds (VOCs), which can be harmful to the atmosphere and human health.

Low-Emission and VOC-Free Powder Finish Formulations

The industry is quickly moving in the direction of low-emission and VOC-free powder covering alternatives. One Precision supply the same level of security and surface as their conventional counterparts however with a fraction of the ecological impact. For producers, this means not only a cleaner conscience but a much safer and much healthier workplace for employees.

Reliable Application and Waste Recovery Equipments

The application of powder finishing can be maximized to minimize overspray and maximize transfer efficiency. In addition, waste recuperation systems can capture and recycle excess powder, minimizing the amount of material that finishes up in land fills. These cooperations not only decrease waste however also reduce the general usage of powder finishes.

By executing these methods and innovations, the sheet metal fabrication sector is not simply discussing sustainability-- it's actively functioning in the direction of it. Each step taken, from the layout process to the finishing touches, plays a part in conserving sources and protecting our planet for future generations. The road to sustainable manufacturing might be long, but the sheet steel industry is proving that with development and resolution, every market can locate its means.