Maximizing Sheet Metal Manufacture for Sustainable Manufacturing

In the context of our advancing ecological awareness, sustainable manufacturing has actually ended up being extra than simply a catchy expression-- it's a duty that the sector must shoulder. One market that's climbing to the difficulty is sheet metal fabrication. This procedure, integral to creating components for a variety of items, can be optimized for sustainability in a myriad of means. Right here's a deep-dive right into exactly how the sheet metal manufacture industry is forging in advance with environment-friendly methods without compromising on top quality.

Eco-Friendly Practices in Sheet Metal Fabrication

For sheet steel manufacture to be sustainable, the beginning factor has to be a conscious effort to lower the environmental impact of the process. This includes every little thing from equipment and product choice to scrap reduction and energy-efficient operations.

The Role of Recycled Materials in Modern Steel Sheet Production

One of the most significant shifts in the direction of sustainability has been the assimilation of recycled products right into the manufacturing of steel sheets. These materials, often ditch metal from previous manufacturing procedures, reduce the need for brand-new ores, consequently preserving all-natural sources and energy. The sector is progressively investing in tools that can deal with a greater percentage of recycled content, making sure that every sheet that's cut and bent is a step towards a greener future.

Lowering Waste via Efficient Sheet Steel Design and Nesting

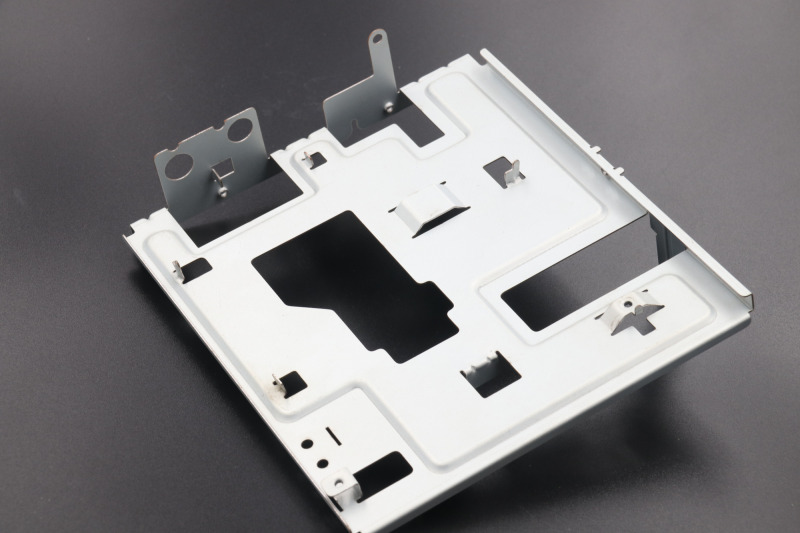

Waste reduction starts with style. By using robot thermomix and advanced computer system modeling, producers can develop reliable part layouts that reduce the amount of unused material. Nesting software further optimizes this procedure by setting up individual components in a manner that decreases scrap and raises the variety of components that can be generated from a solitary sheet. These simple yet effective practices can lead to a considerable reduction in material waste.

Energy-Saving Technologies in the Sheet Metal Sector

The sheet metal market generally consumes a big amount of power due to the heats required for reducing, forming, and ending up. However, breakthroughs in innovation offer options that dramatically reduce power usage without compromising efficiency.

The Fostering of Laser Reducing and High-Efficiency Presses

Laser cutting, with its accuracy and reduced material bending, is not only a game-changer in terms of quality however likewise in energy efficiency. Contrasted to typical mechanical cutting techniques, lasers take in less power and produce less material waste. Similarly, high-efficiency presses require less energy to develop metal, and when incorporated with power recovery systems, can cause significant savings.

Renewable Resource Integration

Numerous forward-thinking sheet metal fabrication centers are relocating towards or have actually currently applied sustainable energy sources, such as solar panels and wind turbines, to power their procedures. This not only decreases the greenhouse gas exhausts connected with standard power generation but additionally shields producers from the volatility of fossil gas costs. In addition, some are transforming to environment-friendly energy tariffs, which sustain the generation of sustainable power.

Sustainability in Powder Finishing Processes

Powder layer, the procedure of using a completely dry powdered paint to a metal part, is one more area where sustainability can be markedly enhanced. Typical fluid paints usually have high levels of unstable natural compounds (VOCs), which can be harmful to the setting and human health.

Low-Emission and VOC-Free Powder Layer Formulations

The sector is quickly moving in the direction of low-emission and VOC-free powder finish alternatives. These formulations still give the very same degree of security and finish as their typical equivalents however with a portion of the environmental effect. For suppliers, this indicates not only a cleaner conscience yet a much safer and much healthier office for staff members.

Effective Application and Waste Recovery Equipments

The application of powder coating can be enhanced to minimize overspray and make best use of transfer effectiveness. In addition, waste healing systems can record and recycle excess powder, lessening the amount of product that winds up in garbage dumps. These cooperations not just lower waste but also reduce the general consumption of powder finishes.

By implementing these approaches and technologies, the sheet steel manufacture sector is not just talking regarding sustainability-- it's proactively functioning in the direction of it. Each step taken, from the design process to the complements, figures in in conserving resources and protecting our world for future generations. The road to lasting manufacturing might be long, yet the sheet steel market is verifying that with advancement and resolution, every industry can find its means.