Opening Precision: The Improvements in CNC Grinding Technology

In the intricate world of production, the accuracy of elements can imply the difference in between top-tier efficiency and failure. One modern technology at the center of this precision game is Computer system Numerical Control (CNC) grinding. This article intends to discover the advancements in CNC grinding innovation, how they revolutionize production, and what the future holds.

The Development of CNC Grinding Machines

The early background of grinding is a story of human hands improving materials to practical precision. With the Industrial Revolution, water wheels and vapor engines mechanized the procedure, yet it wasn't up until the mid-20th century that the initial CNC mills arised. These very early designs changed the production landscape by introducing configured control over grinding courses and stress, removing numerous hand-operated jobs and substantially enhancing throughput.

Fast forward to the 21st century, and today's CNC grinding makers are marvels of accuracy design. They stand as columns of modern production, converting electronic plans into physical fact with sub-micron precision and using a degree of repeatability and control that the previous generations might only dream of.

Exactly How Modern CNC Grinders Enhance Manufacturing Precision

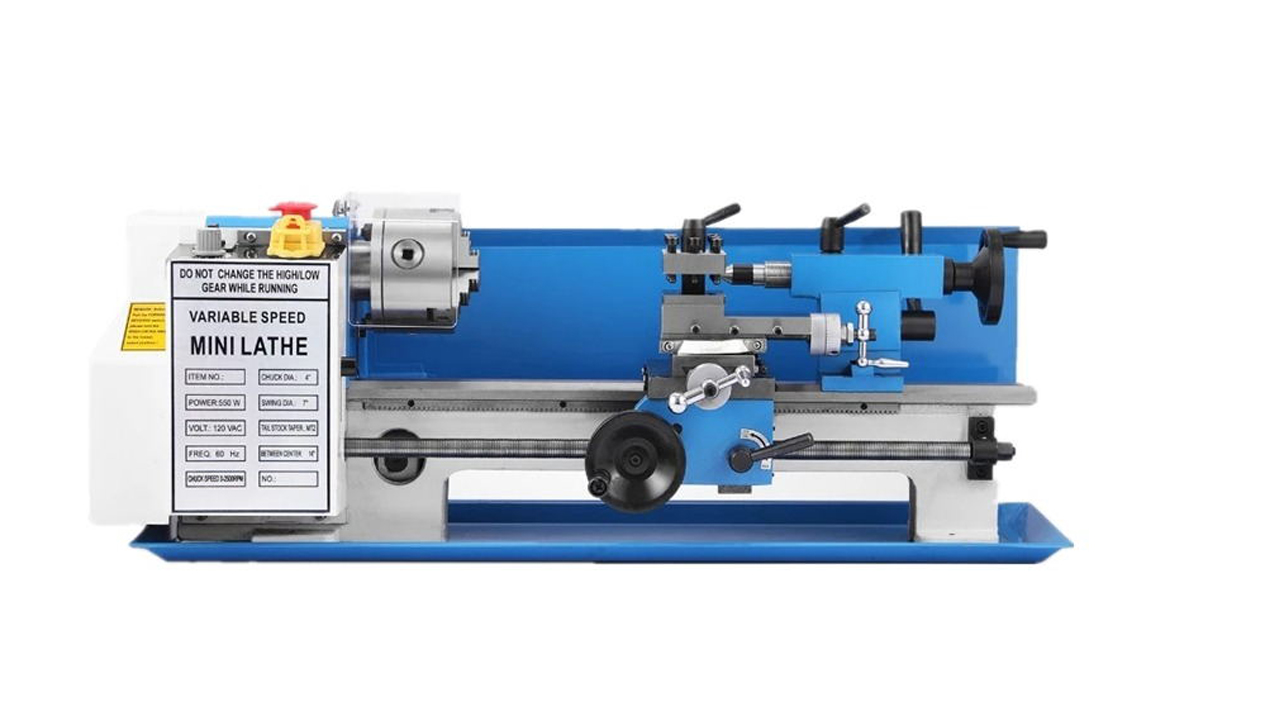

The secret to the precision of modern-day CNC grinders depends on their robust style and advanced control systems. These machines are built to exacting requirements, with high-quality products and rigorous testing to make sure very little resonances or discrepancies. cnc lathe takes care of the placement and turning speed of the grinding wheel however likewise factors in variables such as product firmness, thermal development, and even the age of the rough, all to supply a best surface.

But it's not simply the equipment; the integration of sensors allows real-time changes based on the product's response to the grinding process. This vibrant adaptation implies that the end product specifically matches the digital style, iteration after model.

The Role of Expert System in CNC Grinding

Expert System (AI) has actually taken CNC grinding to the next level. With equipment learning algorithms, CNC mills can optimize their procedures autonomously, picking up from previous tasks to boost efficiency and high quality with time. AI also helps in predictive maintenance, discovering wear and tear on the device parts before they affect result, hence raising uptime.

In addition, AI is breaking brand-new ground with on-the-fly modifications and the ability to deal with much more complicated tasks. It's not almost precision anymore, but concerning versatility to the progressively diverse and custom-made nature of making demands.

Contrasting Typical vs. CNC Grinding Techniques

Comparing CNC grinding to traditional methods is like pitting a smartphone against a landline phone. Standard grinders lack the precision, speed, and control that CNC equipments supply. They are also more labor-intensive and commonly need a higher level of ability to operate, causing a higher margin of mistake and slower turn-around times. CNC grinding, on the other hand, is highly automated, causing decrease prices and quicker deliveries for makers.

Nonetheless, traditional techniques still hold guide in specific areas, especially with very specialized parts or low-volume production runs where the arrangement time for CNC equipments could exceed their advantages.

https://www.senmocn.com/cylinder-block-grinding-machine.html in CNC Grinding Modern Technology

The future looks extremely exciting for CNC grinding innovation. We can expect to see advancements in AI that lead to a lot more autonomous and adaptive makers, capable of handling extraordinary levels of intricacy and variety in production requirements. Additive production, or 3D printing, is anticipated to incorporate with CNC grinding to fine-tune 3D-printed elements at a level of accuracy that is presently testing to attain.

In addition, it is likely that environmental issues will certainly drive the development of more lasting grinding methods. This may entail the use of environment-friendly abrasives or the optimization of device procedures to reduce energy consumption and waste.

Finally, CNC grinding innovation is not simply a gear in the production wheel; it's the very axis around which the contemporary market rotates. Its continuous development is not just a testament to human ingenuity however also a promise of a future where precision design and effective manufacturing are not simply goals yet warranties.