Understanding Insulator End Fittings in Composite Insulators

Insulators are crucial components in high-voltage power transmission systems as they play a crucial duty in maintaining the electric current moving safely. https://www.ttpowerenergy.com/product/insulator-end-fitting/ , also called non-ceramic or polymer insulators, have actually become more preferred as a result of their better performance and longevity. Insulator end fittings are important parts that connect the insulator to the conductor or other elements in a transmission line. In this blog site message, we will certainly explore the value of insulator end fittings, the different types readily available, installment strategies, products utilized in their building, and pertinent criteria.

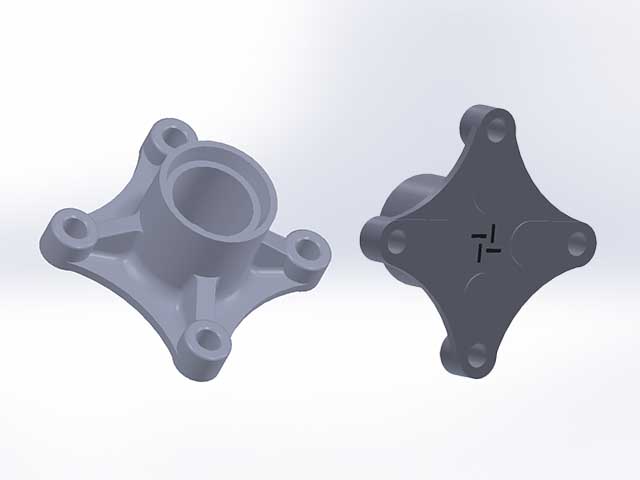

The Function of End Fittings in Composite Insulators:

End installations are crucial parts for composite insulator installation and link. They protect the insulator to the framework and stop it from breaking away from the conductor. https://www.ttpowerenergy.com/product/ offer a trustworthy mechanical user interface in between the insulator and the framework, making certain that the insulator's load-carrying capacity is not jeopardized. They are likewise liable for moving the tensile and compressive lots from the insulator to the tower or pole and absorbing any type of flexing moments.

Types of End Fittings: A Thorough Introduction:

There are a number of types of insulator end installations offered, depending on their application and framework type. One of the most typical ones consist of ball-and-socket, tongue-and-clevis, socket-eye, and yoke fittings.

Ball-and-socket fittings consist of a ball-socket combining that permits for angular activity along a radial airplane, making them optimal for locations with high wind loads. Tongue-and-clevis installations offer comparable angular motions however with less resistance to axial lots. They are one of the most frequently used fitting in above transmission lines. Socket-eye installations give a safe straight-line pull and are typically utilized where the insulator axis needs to be according to the conductor axis, while yoke installations are for usage when the conductor requires to be kept in a set placement.

Installment Techniques for Insulator End Fittings:

End fittings can be installed utilizing different methods, depending upon the operational situations and the design requirements. One of one of the most common techniques is the crimping method, where end installations are affixed to insulators using a particular crimping tool. Another strategy is the mechanically lined strategy, which includes permanently connecting the metal end suitable to the insulator making use of epoxy adhesive. The injection molding technique involves infusing the polymer product right into the metal end suitable, permitting a strong bond in between the 2 materials.

Product Option for Sturdy Insulator End Fittings:

The choice of product for insulator end fittings plays a vital function in their long life and toughness. One of the most generally used products are light weight aluminum, steel, and composite products. For ball-and-socket installations, aluminum is a preferred selection as a result of its high strength-to-weight proportion and rust resistance. For tongue-and-clevis installations, steel is normally used due to its high toughness and rigidity. For socket-eye installations, both steel and light weight aluminum are typically utilized, while composite materials are made use of for yoke installations due to their outstanding insulation and corrosion-resistant residential properties.

Requirements and Regulations Governing Insulator End Fittings:

To make sure the security and integrity of power transmission systems, several requirements have actually been developed to regulate the layout, testing, and manufacture of insulator end fittings. A few of these standards include IEC, ANSI, and GB criteria, which cover essential elements such as mechanical stamina, electric residential properties, and environmental performance. Furthermore, regulatory bodies, such as the National Electric Safety And Security Code (NESC) and the Occupational Safety and Wellness Management (OSHA), have actually also developed standards to govern the risk-free procedure and maintenance of transmission lines.

Insulator end installations are vital elements in the power transmission system, and their correct installment, material option, and adherence to standards are critical for system safety and security and integrity. Understanding the various types of end installations readily available, setup methods, products, and requirements can aid system operators and designers make notified choices when choosing and installing insulator end installations. They additionally play an essential role in the system's overall sustainability by ensuring that power is provided securely and effectively.